Take your research in any direction with the new benchmark for Raman imaging.

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

Polymers play a key role in modern materials science. Due to their diverse mechanical and chemical properties, they are used in nearly every application field, from everyday products to automotive parts and high performance materials. Their versatility and complexity are vital for the creation of sustainable, next-generation materials designed to meet increasingly intricate demands in both characteristics and tailored production processes. Our Raman microscopes support this innovation by providing comprehensive, non-destructive sample analysis at the nanometer scale and offering detailed insights into chemical and physical attributes. This aids researchers and engineers in accelerating innovation and discovery, and ensuring quality and efficient product development.

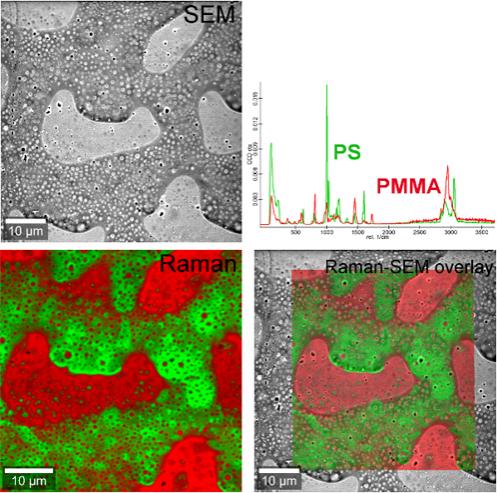

Our modular witec360 microscopes can combine Raman imaging with additional imaging techniques, including AFM, SNOM or SEM, to gain more comprehensive insights into your polymer materials. While Raman imaging captures molecular information, AFM characterizes the topography and properties such as stiffness and adhesion of the sample’s surface. SNOM allows optical measurements to extend beyond the diffraction limit, and RISE integrates Raman with SEM for ultimate chemical sensitivity and structural resolution. All instrument configurations can be upgraded at any time to accommodate new or expanded requirements.

Read more about correlative Raman imaging of polymer materials in our Application Note.

Polymerization reactions play a crucial role in many manufacturing processes. Scientists involved in polymer research and industrial manufacturing need analytical methods that can visualize the intricacies of these reactions to optimize both the processes and the final products. Raman microscopy serves as a beneficial tool for in-situ observation of these polymerization reactions. For instance, Raman imaging allowed us to observe the polymerization of an alkyd resin varnish over a 24-hour period, and to visualize the spatial distribution of the reaction components at each individual time point.

Read more about the measurement here.

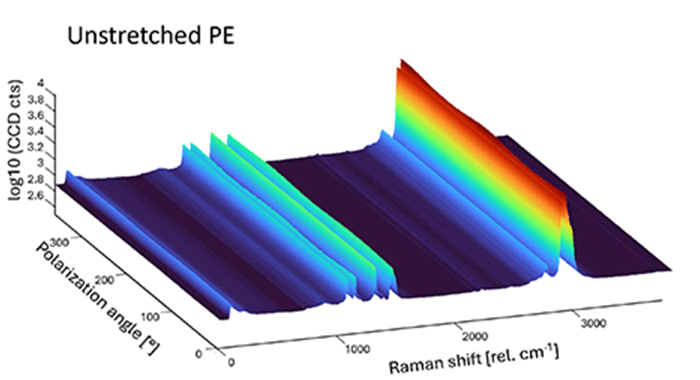

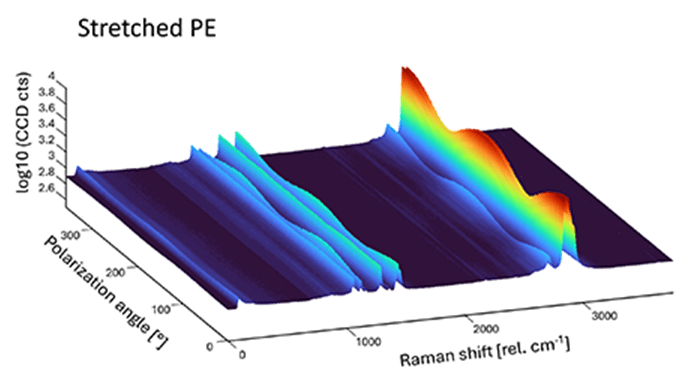

The molecular structure and arrangement of polymer fibres within plastic materials significantly influences the polymer’s physical properties such as stability, flexibility and transparency. Polarization-resolved Raman analyses can help determine the material’s molecular structure and identify the orientation of the polymer fibres. In a study conducted at the Swiss Federal Laboratories of Materials Science and Technology (Empa), we used polarization-resolved Raman microscopy to resolve the orientation of polyethylene fibres in a plastic wrap. This allowed us to characterize the alignment of fibres within the material under stretching conditions.

Learn more about our polarization-resolved imaging options and read more about the study in our Technical Note.

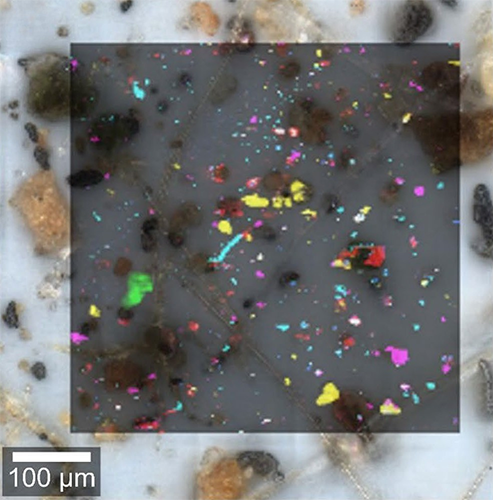

For a simplified analysis of microplastic particles, discover our ParticleScout imaging option. ParticleScout delivers prompt and straightforward Raman results, allowing for the precise characterization and identification of microplastics in samples from environmental science, food technology, pharmaceuticals, cosmetics and industrial applications.

If you'd like to learn more about the possibilities of Raman imaging for polymer applications, one of our specialists will be happy to discuss them with you.

Contact us