Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

alphaCART’s Raman probe can be flexibly positioned in front of bulky, immovable or precious objects that can’t be transported to a microscope or that don’t fit under one.

The system's high confocality and signal sensitivity also allow measurements through protective glass and windows, which enables studies of gases or chemical processes inside reaction chambers and other enclosures. Researchers working in the arts and archaeology, geo- or materials science will especially benefit from this versatile and powerful analytical tool.

The alphaCART system leverages the advanced optics and modular design of Oxford Instruments’ witec360 Raman microscopes and profits from the company’s longstanding expertise in fiber coupling technology. Laser, probe and spectrometer are connected through optical fibers, ensuring the highest signal throughput and optimal beam shape. Thus, alphaCART provides the same diffraction-limited spatial resolution and confocality and superior signal sensitivity as all witec360 systems.

alphaCART is available in different configurations to meet your specific requirements regarding excitation wavelength and spectrometer set-up. For detailed sample survey, white-light illumination and a color video camera are available. Data acquisition and post-processing are controlled through our integrated Software Suite.

The complete stand-alone alphaCART system is bundled into a compact rolling flight case for easy and safe transport to experiments in the field. Additionally, the Raman probe can be connected to a stationary witec360 microscope to extend its flexibility within a lab.

The positioning flexibility of the alphaCART probe combined with its high confocality and signal sensitivity enables the nondestructive analysis of:

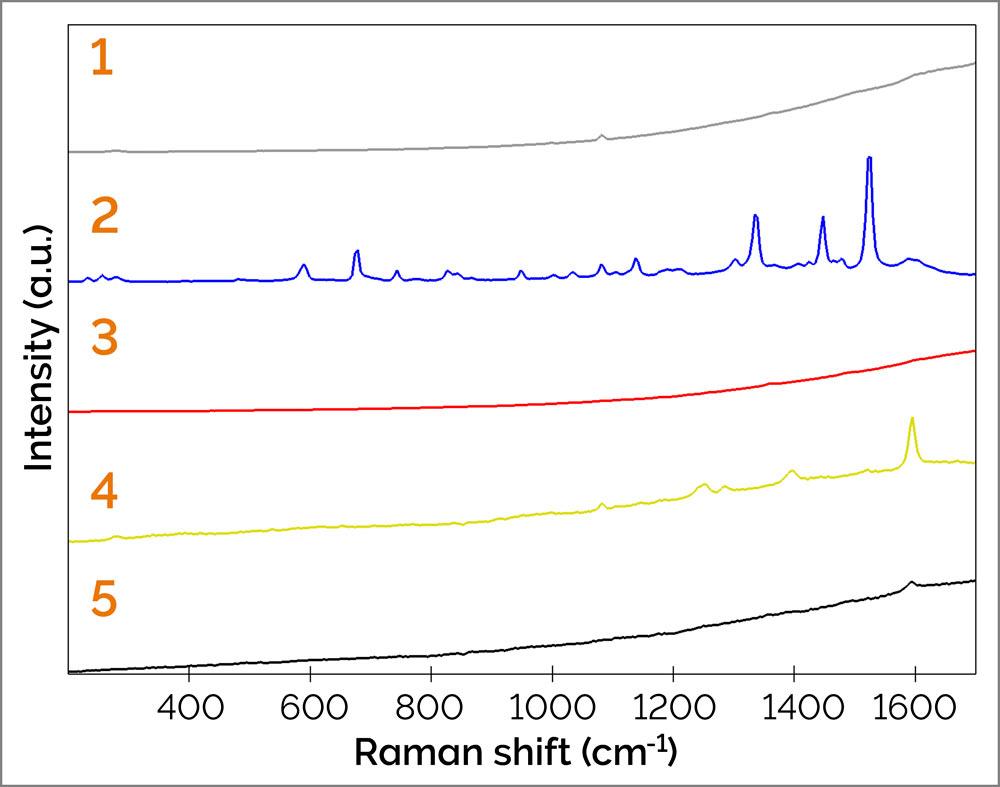

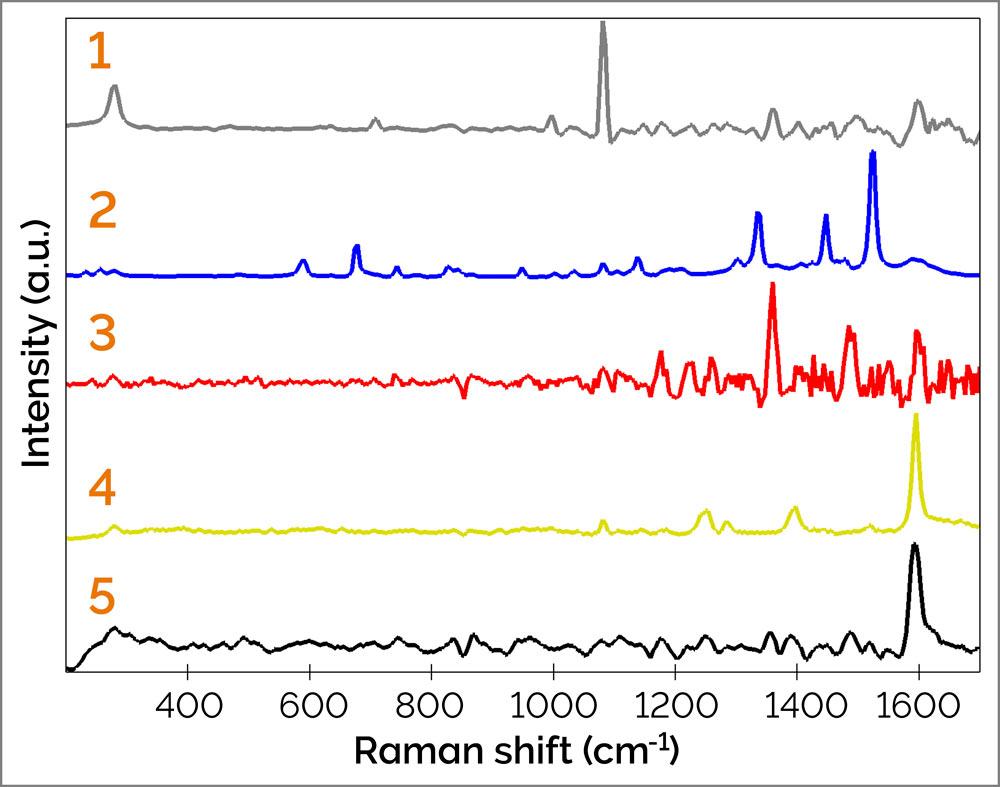

alphaCART’s high confocality and sensitivity enable Raman analyses of fluorescing materials and weak Raman scatterers, even if the sample is behind protective glass or inside an enclosure.

For illustration, the Raman probe was positioned in front of a framed poster showing a portrait of Sir C. V. Raman. Using the alphaCART’s white-light illumination and video camera, a part of the poster was magnified, showing differently colored ink spots. The raw Raman data recorded at different positions with a 532 nm laser was partially obscured by the high fluorescence background from the paint. However, applying efficient background subtraction algorithms revealed the Raman spectra of the various pigments and of the coated paper. Due to the system’s high confocality, the protective glass in front of the poster remained outside of the focal plane of the measurement, reducing the fluorescence background and enabling the detection of the Raman signals.

Being a portable system, alphaCART can be used for investigating objects that can’t be moved into a lab. It was brought to the Kunsthistorisches Museum in Vienna, Austria, to conduct the most thorough analysis to date of the Imperial Crown of the Holy Roman Empire.

Raman and photoluminescence measurements of the Imperial Crown’s 172 gemstones were performed in the Imperial Treasury in Vienna by researchers from the Institute of Mineralogy and Crystallography at the University of Vienna. The study provided detailed insights into this historic treasure, which were published in the Journal of Gemmology (DOI: 10.15506/JoG.2023.38.5.448).

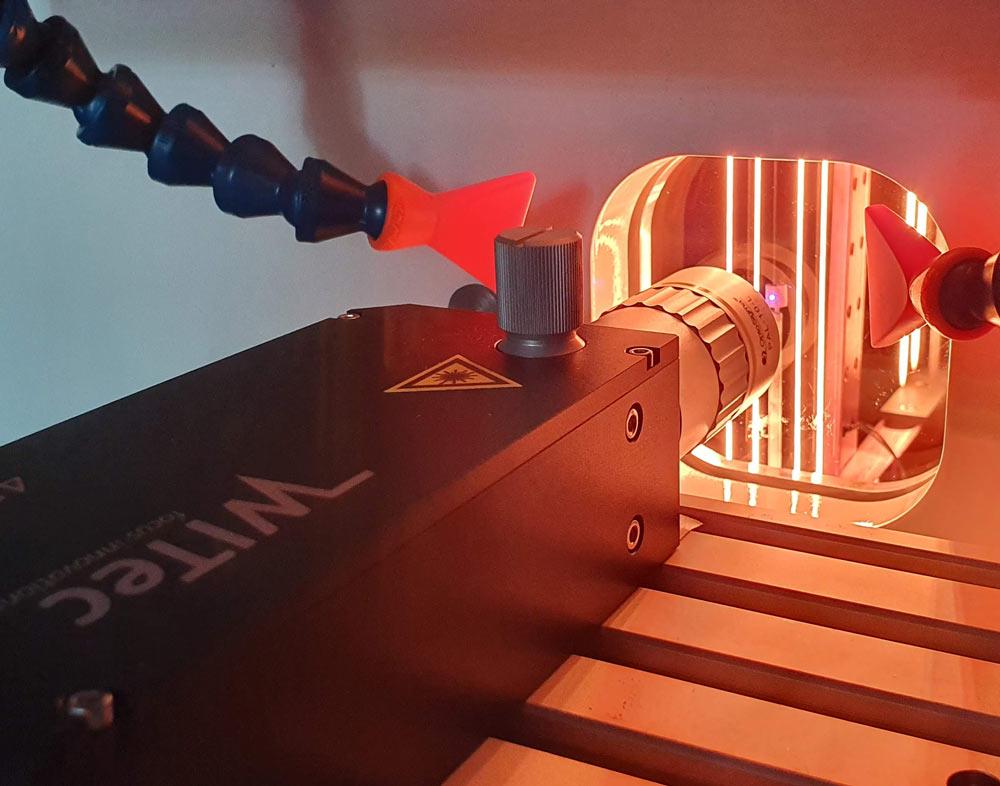

alphaCART is ideally suited to monitoring chemical processes inside reaction chambers. In this example, the diamond coating of a steel tool was observed in situ through the window of a hot-filament chemical vapor deposition (HF-CVD) reactor. The Raman probe was equipped with a long working distance objective. Its high sensitivity and confocality enabled the detection of the relatively weak Raman signals from the thin diamond layer despite the black-body radiation of the hot sample.

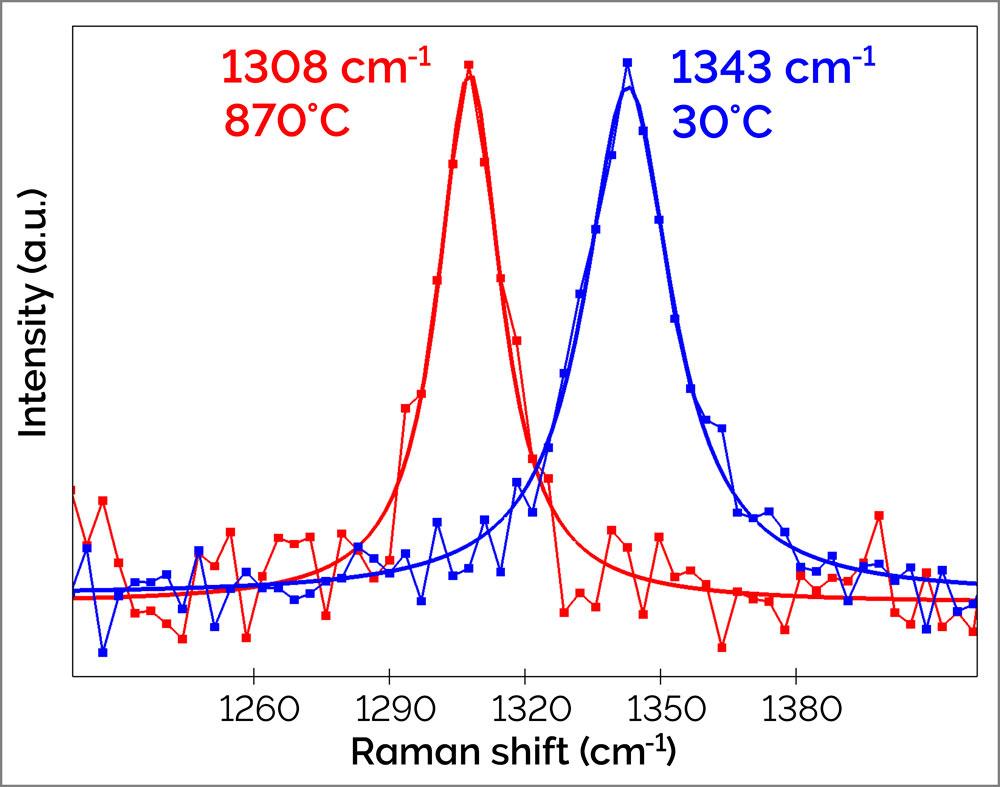

Diamond coatings are applied to many machine tools and mechanical components for their hardness, chemical inertness and wear resistance. In situ chemical characterization of the material is beneficial for optimizing production methods, for example, to minimize stress in the finished tool. By positioning the alphaCART Raman probe in front of the HF-CVD reactor, temperature-dependent Raman spectra could be obtained from the diamond material during the entire coating and subsequent cooling process. From the Raman spectra, the temperature-dependent diamond peak positions (around ca. 1330 cm-1) were quantified. After subtracting the temperature-dependent Raman shift, thermal stress and the quality of the diamond layer could be determined and conclusions were drawn about crystallographic modifications in the steel substrate.

Details about this study performed at the Chair of Materials Science and Engineering for Metals (WTM), Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU), Germany, are published in:

Helmreich et al. (2025) In situ Raman spectroscopy of thermal stress in diamond on steel during HF-CVD coating and subsequent quenching. Vacuum 240: 114563 DOI: 10.1016/j.vacuum.2025.114563, Licensed under the Creative Commons CC BY 4.0Read the paper

Please fill in all data fields to ensure we can process your inquiry as quickly as possible.